We carry out mechanical machining on different types of materials: common steels, alloys, special steel, stainless steel, special alloys (inconel, astelloy, titanium etc.), light alloys (anticorodal, ergal, avional, etc.). All materials have relative quality certification.

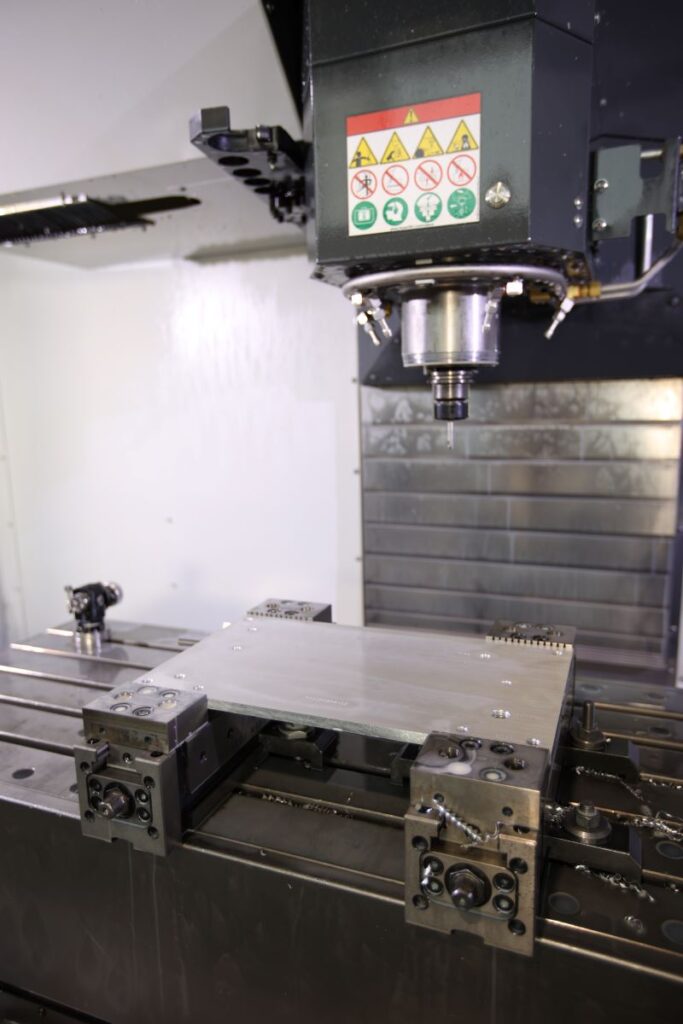

The production department is equipped with CNC machining centers, lathes and mills with up to 5 axes. The company has always believed and invested in technology, guaranteeing a park cutting-edge machines, managed by motivated and highly qualified personnel.